Recently, Xingcheng Special Steel Works of CITIC Pacific Special Steel Group constructed with the assistance of CERI Digital Technology Co., Ltd. showcased on CCTV News Channel. Our modernization initiative was highlighted on the CCTV News live broadcast for jointly exploring the intelligent password of lighthouse factories.

Xingcheng Special Steel Works has extensively integrated artificial intelligence technology into product research and development as well as production processes. This shift has allowed the company to move away from inefficient trial-and-error methods and achieve adaptable customization, embodying the pinnacle of digital manufacturing. By establishing a "lighthouse factory", the company is lighting the path for the future of manufacturing and spearheading the high-quality development of the industry.

In driving the digital transformation of Xingcheng Special Steel Works, CERI has developed products leveraging industrial Internet platform architecture, including quality big data analysis, refined energy management, full-process control of carbon emissions, and digital twin platform. These innovations have facilitated significant advancements for Xingcheng Special Steel Works in quality control, tailored business solutions, industrial Internet platform integration, and efficient energy-saving operations.

Quality big data analysis integrates the quality data of all factors within the system, enabling comprehensive information collaboration throughout the process and the alignment of operational parameters with quality standards. Real-time assessment of steel quality allows for immediate scoring of operations and the prompt development of corrective measures, facilitating closed-loop management of production transparency and timely inter-process feedback.

Refined energy management addresses the challenges of high complexity, low refinement, supply security pressures, and high-risk environments in enterprise energy management. In accordance with the status of manufacturing processes and equipment, lean methodologies are employed to analyze energy consumption, unlock energy efficiency potential, and achieve closed-loop optimal scheduling through coordinated efforts with intelligent production scheduling, quality big data, and equipment health prediction systems, so as to maximize energy utilization.

The full-process control of carbon emissions involves analyzing the enterprise's carbon emissions, establishing plant-wide carbon flow, implementing carbon accounting and data analysis functions to monitor product carbon footprint. This ensures refined carbon emission management across Xingcheng Special Steel Works' factories, workshops, processes, and equipment. The ultimate aim is to reduce carbon emissions and promote environmental sustainability.

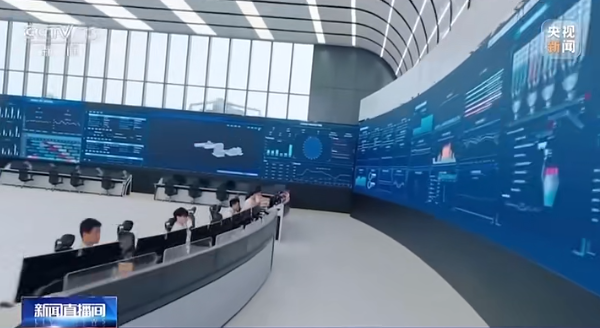

The digital twin platform, based on Smeltery Rolling Workshop I, creates twin scenarios through model construction, all-round data integration, and knowledge solidification and training. It integrates various business systems including MES, energy, environmental protection, safety, equipment, and big data systems, establishing a digital factory architecture with CeriOS industrial Internet platform as the framework and digital twin map as the foundation. This architecture centers on digital intelligent control building. Twin applications have been deployed at plant-wide, workshop, and equipment levels to enhance production control efficiency.

As a top innovator of digital and intelligent products and a pioneering provider of intelligent manufacturing solutions in China, CERI facilitates enterprises' digital transformation and industrial advancement with end-to-end solutions spanning intelligent design, equipment, control, and management. Going forward, CERI will persist in leveraging scientific and technological innovation as the cornerstone, harnessing digital technology as the catalyst to drive high-quality growth, empower more "lighthouse factories", and illuminate the path to intelligent industrial production in the future.