The Primary Dedusting Transformation Project in operation at No.1 and No.2 Converters for Jilin Jianlong Steel Works

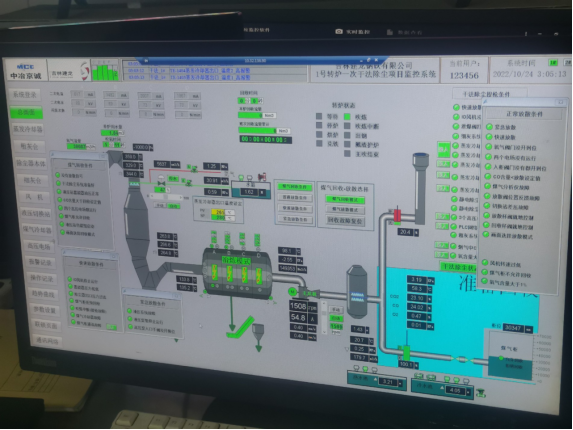

After 17 days of successful hot test run of the primary dry dedusting system of No. 2 converter in the steel works of Jilin Jianlong Iron and Steel Co., Ltd. in early October, the primary dry dedusting system of No. 1 converter was successfully put into operation on October 22, three days ahead of the contract period, and gas recovery was achieved after three heats. Through nearly half a month of operation assessment, up to now, the two sets of primary dry dedusting equipment have been in good operation with excellent indicators.

Jilin Jianlong has two 150t top-bottom combined blowing converters. The original dedusting process is OG wet process, in which frequent equipment cleaning is required. According to the requirements of the national policy on energy conservation and emission reduction and the strategic development plan of the enterprise, in order to further achieve energy conservation and consumption reduction, eliminate and improve backward production processes and equipment, the dry dedusting process is adopted for the primary flue gas dedusting of the converter, and the layout location and relevant interfaces of fine dedusting transformation equipment are reserved to meet the higher standards of subsequent environmental protection emissions.

The first concrete pipe pile was driven on May 5, 2022, the handover and acceptance of the electrostatic precipitator foundation was completed on June 18, the lifting of the ring beam of No. 1 electrostatic precipitator was finished on July 16 and the lifting of the ring beam of No. 2 electrostatic precipitator was completed on July 30. The installation of anode plates and cathode wires of No. 2 electrostatic precipitator was completed and the sealing of top cover was started on September 1. On September 16, the furnace was officially shut down, and the removal of the wet dedusting equipment and the installation of the dry dedusting equipment in the converter workshop was started. It took only 37 days to successfully put the two converters' primary dry dedusting into operation and complete the gas recovery, handing over a satisfactory answer sheet to the owner.