CERI: Leveraging Green Intelligent Manufacturing to Help Donghua Steel Open a New Chapter in Upgrading

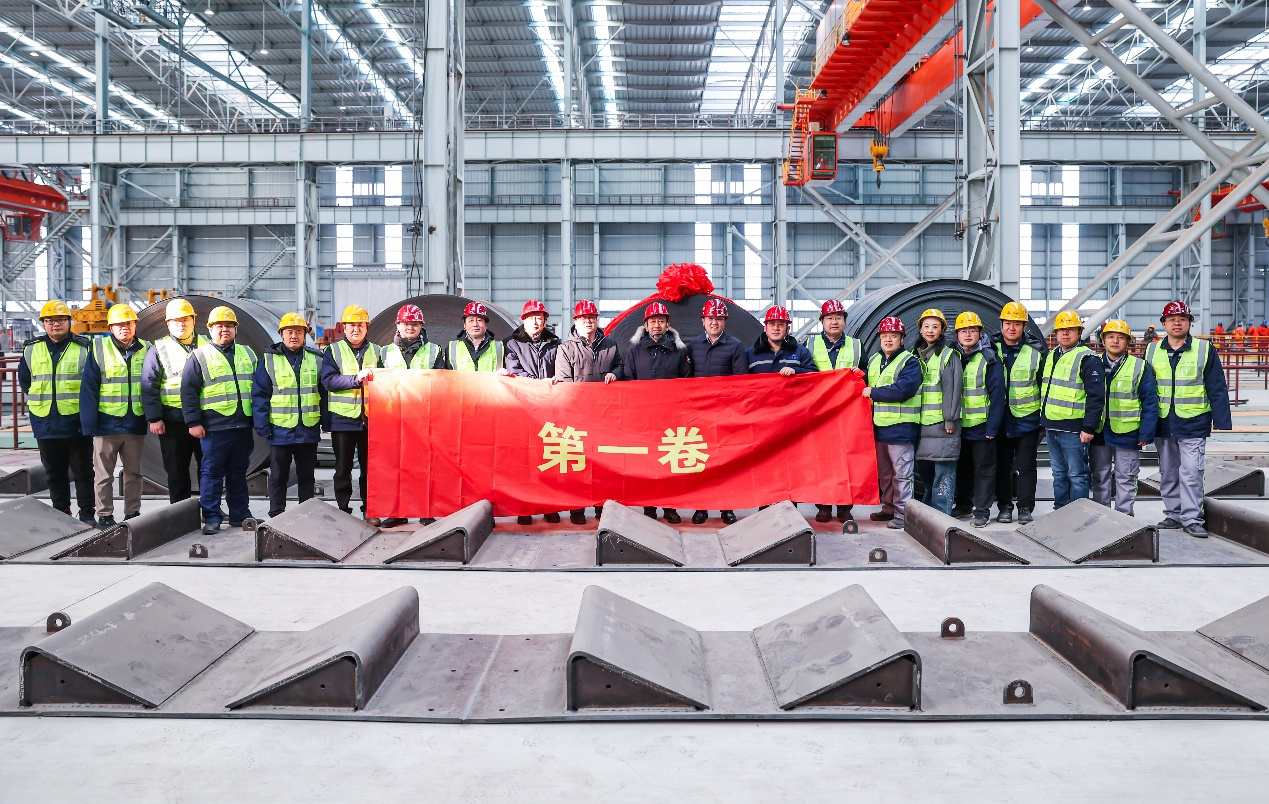

Recently, Tangshan Donghua Steel has made significant progress with the official launch of its 1580mm hot-rolled wide strip steel project, marking an important milestone in the project construction. This project encompasses the entire industrial chain, including facilities for steelmaking, hot rolling, and pickling. Driven by advanced processes, intelligent control, and green technology, the project promotes the transition of iron and steel enterprises towards high-end, intelligent, and low-carbon production.

Building a Foundation with Technology and Forging a New Engine for High-End Production Lines

The Tangshan Donghua Steel Projects are extensive in scale and involve substantial work quantities, featuring 1 BOF, 3 continuous casting machines, 2 heating furnaces, one 1580 mm hot-rolled wide strip steel production line, 1 pickling and skin passing line, as well as gas holders, production water supply systems, factory roads, and various utilities. Under CERI's meticulous organization and efficient management, these projects have been steadily progressing since their inception. For the first time, our team has implemented a full-line EPC contracting model for the hot-rolled wide strip steel project, integrating internationally leading process technology. This production line incorporates key equipment such as 2 heating furnaces, a four-high reversible roughing mill, a 7-stand finishing mill, and an intelligent inspection system. It is capable of producing more than ten types of high value-added products, including carbon structural steel, low-alloy high-strength steel, and pipe steel, significantly optimizing the product mix of the steel enterprise. The desulfurization, denitration, dust removal, and water treatment systems have been introduced simultaneously, achieving a strong synergy between production and environmental protection. To date, four projects, including the pickling and skin passing line, water treatment, 220kV substation, and steelmaking, have been put into operation. The commissioning of the 1580mm hot-rolled wide strip steel main line stands as a crucial milestone for the overall success of these projects.

Digital-Driven Creation of a New Lifecycle Paradigm

By leveraging digital empowerment to enhance whole-process innovation, the project team has pioneered the development of a digital design system specifically for hot continuous rolling engineering. This initiative extends the application of digital design results across the projects, fully integrating the entire lifecycle, including design, construction, operation, and maintenance, to ensure value addition and efficiency improvements. During the project design and engineering implementation phases, 3D collaborative design of construction drawings was performed, successfully achieving the objective of generating a large volume of 3D design drawings. Utilizing 3D models for design verification allowed for further optimization of the layout for maintenance accesses and operating platforms. Additionally, our self-developed software was employed to complete the 3D design and drawings for cable laying, successfully achieving the goal of digital delivery. The 3D collaborative design system established for this project has effectively addressed digital bottlenecks, such as the challenges of multi-disciplinary integration and the complex process systems inherent in metallurgical engineering. This advancement fills a gap in the comprehensive 3D design of hot continuous rolling, providing a replicable implementation path for the digital transition of traditional metallurgical engineering and ushering the industry into a new era of 3D digital design.

Empowered by Management, We Enhance a Robust and Efficient Contract Performance Guarantee Network

In response to the challenges posed by substantial work quantities and high construction complexity, the project team has implemented a strategy focused on honest contract performance, lean construction, digital empowerment, and safety oversight. To facilitate full-process management, we established one command center and five specialized project departments dedicated to steelmaking, hot rolling, pickling and skin passing, water treatment, and the 220kV substation. During contract performance, we enhance project management and operating budgets through procurement in advance, risk classification control, and resource coordination, ensuring a solid and detailed approach that addresses subcontracting integration and mitigates weather-related challenges. During construction, initiatives like "Quality Month" and "QC Group" serve as platforms, supported by a schedule list and a responsibility mechanism to guarantee the precise execution of key milestones. To ensure safety, we have pioneered a grid management approach, dividing the construction site into responsibility grids to effectively reduce costs associated with temporary facilities by integrating permanent and temporary works.

Fruitful Achievements Pave the Way for a New Blueprint in Implementing the Dual Carbon Strategy

The full commissioning of the Tangshan Donghua Steel Projects is set to significantly enhance both production efficiency and environmental protection efficiency. Economically, the proportion of high value-added products has risen markedly, enabling the steel company to improve quality and efficiency. Ecologically, the integration of ultra-premium energy efficiency and green, low-carbon technologies will effectively reduce carbon dioxide emissions during the production process, supporting the achievement of the "dual carbon" goals. The project has fostered the development of several outstanding teams in areas such as 3D design and safety management. As a model project for the green transition of the steel industry, the Tangshan Donghua Steel Projects offer a replicable upgrade path for the entire sector through a collaborative approach that combines technology, management, and ecological considerations, showcasing CERI's comprehensive strength in the field of EPC contracting.