CERI's Three Technologies Listed Among the Top Ten Technological News in the Global Steel Industry

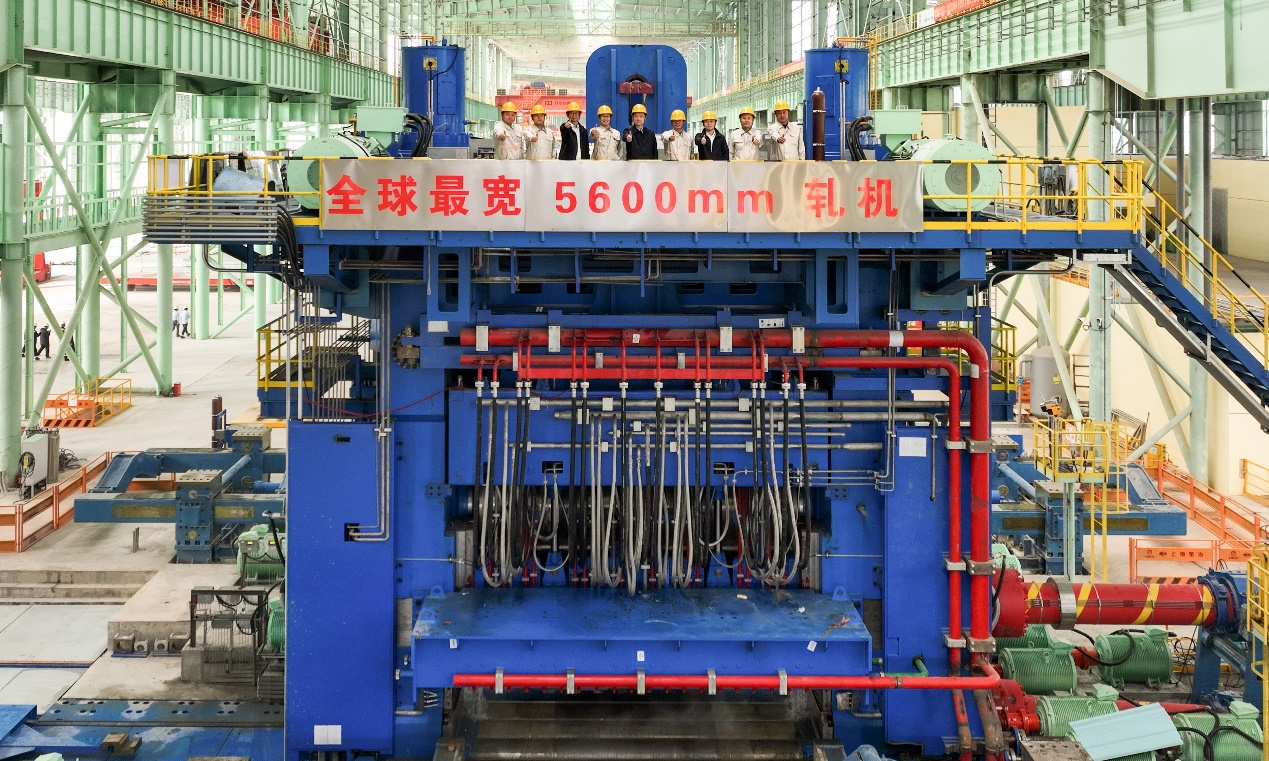

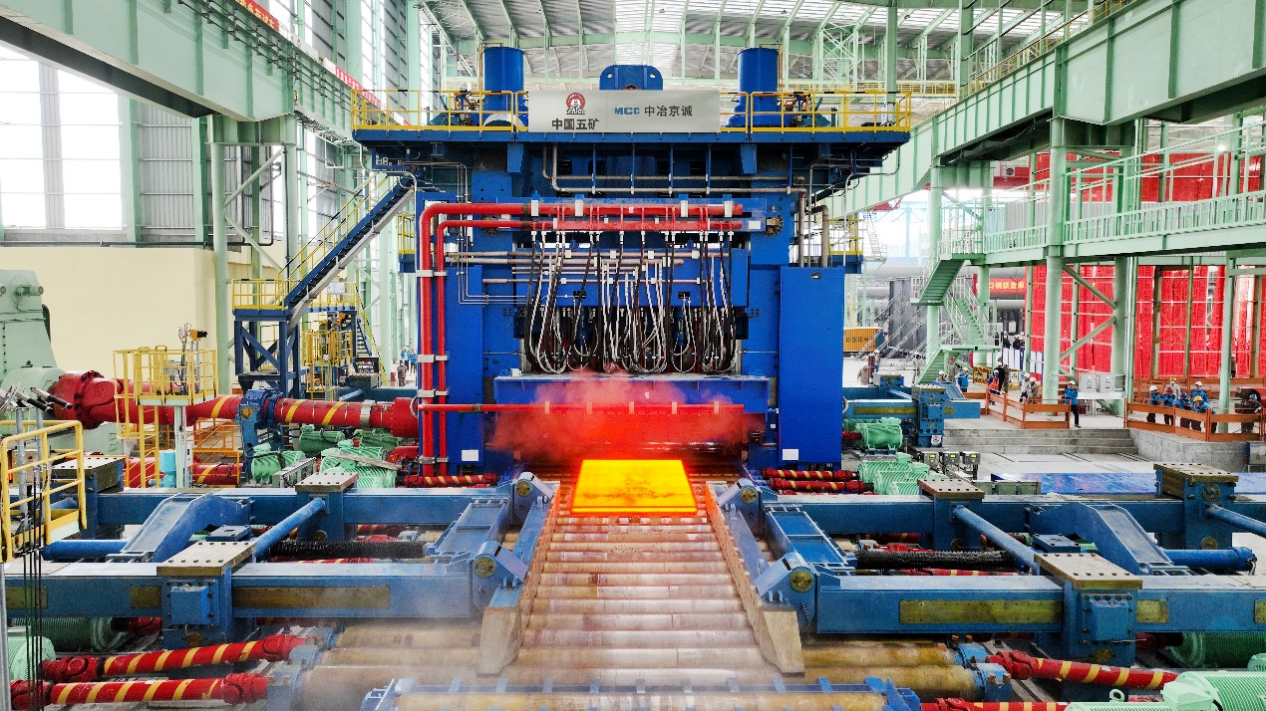

The World’s Widest Heavy Plate Rolling Mill Successfully Completed at Henan Zhoukou Steel

On October 31, 2024, the 5600 mm wide heavy plate roughing mill at Henan Zhoukou Steel, the world's widest heavy plate rolling mill designed and supplied by CERI, successfully completed hot commissioning on its first attempt. This mill features a rolling force of 120,000 kN, a maximum backup roll diameter of 2,400 mm, and a mill stiffness of 9,500 kN/mm. The successful completion of this hot commissioning marks the advent of the 5600 mm era in wide heavy plate rolling.

As core equipment in the rolling and forming process, the rolling mill plays a critical role in determining the quality of heavy plate products. Previously, the existing 5000 mm heavy plate rolling mills in China relied on imported foreign technologies. To achieve self-reliance in core equipment technology, CERI's heavy plate team utilized the design and manufacturing experience gained from the Yingkou 3800 mm and Liuzhou Steel 3800 mm double-stand rolling mills, coupled with an innovative spirit, to undertake the design and supply of this 5600 mm roughing mill for Henan Zhoukou Steel, the widest heavy plate mill in the world.

The mill features advanced technologies developed and integrated by CERI's heavy plate rolling mill team. The mill components were manufactured by CITIC Heavy Industries, achieving metallurgy equipment manufacturing parameters at limit values. Notably, the net weight of a single mill housing approaches 450 tons, with around 860 tons of molten steel used for seven-ladle combined casting, reaching extreme casting limits. The backup rolls weigh nearly 270 tons with a length of approximately 12,000 mm, forged using vacuum smelting and casting technologies with nearly 500 tons of steel ingots, and treated with differential temperature heat treatment and top-support combined ultra-heavy grinding technologies to achieve an overall accuracy within 0.02 mm.

Two Technologies Used in the Construction

The World’s First Hydrogen Metallurgy Green Automotive Plate Continuous Casting Line Put into Operation

On December 16, 2024, the commissioning ceremony for the world’s first hydrogen metallurgy green automotive plate continuous casting line was held at HBIS Zhangxuan Tech.

The 1# slab continuous casting machine boasts the first straight-arc green slab continuous casting machine in China, with the main equipment supplied by Primetals and other equipment contracted to CERI as the EPC contractor. The billet dimensions are 230 mm (with 250 mm reserved) × 1900 mm. The line can achieve an annual output of 1.5 million tons of compliant billets. The project incorporates over 20 advanced technologies, including a mold expert system, mold breakout prediction, remote online width adjustment of the mold, automatic control of mold level, and hydraulic oscillation of the mold. It demonstrates the highest level of technological innovation in the industry and highlights CERI's leading expertise in slab continuous casting technology.

The successful commissioning of this project signifies HBIS's attainment of a complete green automotive plate process chain, integrating the hydrogen-based shaft furnace, green arc furnace, and slab continuous casting machine, thereby establishing a low-carbon green steel production chain. It provides better solutions for the sustainable development of the iron and steel industry. This achievement positions HBIS as a pioneer and benchmark for green and low-carbon transition in both the industry and the country. Furthermore, this project showcases China's pragmatic actions and innovative efforts in maintaining leadership in the green and low-carbon development of the global steel industry. It also serves as another example of CERI's commitment to exploration and practice in the realm of green steel production and manufacturing.

Ø1000mm Super-Large P92 Continuous Casting Round Billet Marks Domestic Debut

The large round billet continuous casting machine for the Baowu Masteel New Special Steel Project represents a typical engineering achievement completed by CERI on an EPC basis.

This continuous casting machine is a critical component of the Masteel New Special Steel Project, for which CERI handled the overall design, continuous casting unit, rolling unit, water treatment, and landscaping. The core technology and equipment are supplied by Danieli, while CERI contributed by providing supporting facilities and construction services. The 3# large round billet continuous casting machine enhances Masteel's capabilities in producing large round billets, thereby expanding its range of new special steel products and improving economic benefits.

CERI is a leading supplier and integrator of large round billet continuous casting machines for high-quality and special steel products. Leveraging extensive design innovation capabilities and accumulated experience, CERI offers comprehensive services from design consulting to equipment upgrades and smart transformations, which has garnered widespread recognition and acclaim in the industry. It has successfully designed and executed multiple large round billet continuous casting lines for prestigious domestic special steel enterprises such as Jiangyin Xingcheng Special Steel Works Co., Ltd., Hunan Hengyang Steel Tube Group Co., Ltd., Jiangsu Lianfeng Steel, and Anhui Wuhu Xinxing Ductile Iron Pipe Co., Ltd. The successful large round billet continuous casting machine for the Masteel New Special Steel Project has not only strengthened CERI's position in the field of large-section continuous casting machine construction but has also reaffirmed its role as a leader and pioneer within the "National Metallurgical Construction Team”.