CERI Launches Demonstration Project for Carbon Dioxide Capture and Liquefaction Technology

Focusing on the "dual carbon" strategy and developing new-generation carbon capture technology

In response to the considerable and cost-effective carbon reduction needs of the iron and steel industry, MCC Capital Engineering & Research Incorporation Limited (CERI) is dedicated to overcoming the challenges. Through research, CERI has identified that while many current carbon dioxide capture projects have proved the feasibility of the technology, operational cost-effectiveness remains a challenge. The capture process introduces additional energy consumption, which impacts the overall energy efficiency of the process. CERI has conducted a thorough analysis of the main challenges currently facing carbon reduction technologies, including economic costs, technical maturity, and large-scale application. We are exploring the use of new capture materials, such as adsorbents and membranes, while also enhancing existing chemical absorption methods. These efforts aim to lower carbon dioxide capture costs and energy consumption while improving capture efficiency, thereby ensuring both economic viability and practicality. Focusing on carbon dioxide capture and utilization technologies suitable for the metallurgical industry, CERI is addressing technical challenges such as high absorption energy consumption, poor oxidation resistance of absorbents, degradation and deterioration of materials, and high corrosiveness in chemical absorption methods. As a result, CERI has successfully developed a new carbon dioxide capture technology primarily utilizing a two-phase absorbent.

New Absorbent Developed to Address Technical Bottlenecks in Regeneration Energy Consumption

CERI has developed a phase-change capture solvent characterized by low energy consumption, low corrosiveness, and a high desorption rate. This absorbent combines advantageous physical properties, such as low viscosity and a high boiling point, with exceptional chemical properties that ensure high carbon dioxide absorption and desorption efficiency. Once the absorbent captures carbon dioxide, it exhibits the ability for self-driven concentration and stratification, forming rich liquid and lean liquid without requiring additional energy. This reduces the water content of the rich liquid, leading to a decrease in the overall liquid volume entering the regenerator. Consequently, this process minimizes the size of the regenerator and lowers regeneration energy consumption. Compared to traditional MEA capture solvents, this new absorbent demonstrates over a 30% increase in carbon dioxide absorption capacity while also reducing regeneration energy consumption by more than 20%.

Innovative Integrated New Energy-Saving Process Featuring Interstage Cooling and Cascade Waste Heat Utilization

To address technical challenges such as the high cost of reaction equipment and the difficulty in utilizing low-temperature and low-pressure waste heat, CERI has developed high-performance towers and energy-saving equipment to enable multi-stage capture process system coupling. We have established an efficient heat and mass transfer system to enhance the heat and mass transfer processes. Additionally, improvements to the internal structure of the absorption system have further optimized heat and mass transfer. By increasing the absorbent load and reducing the volume of the circulating absorption solution, we achieve efficient and energy-saving capture and absorption of carbon dioxide from flue gas.

First Pilot Plant in the Industry with a Capture Rate of 90%

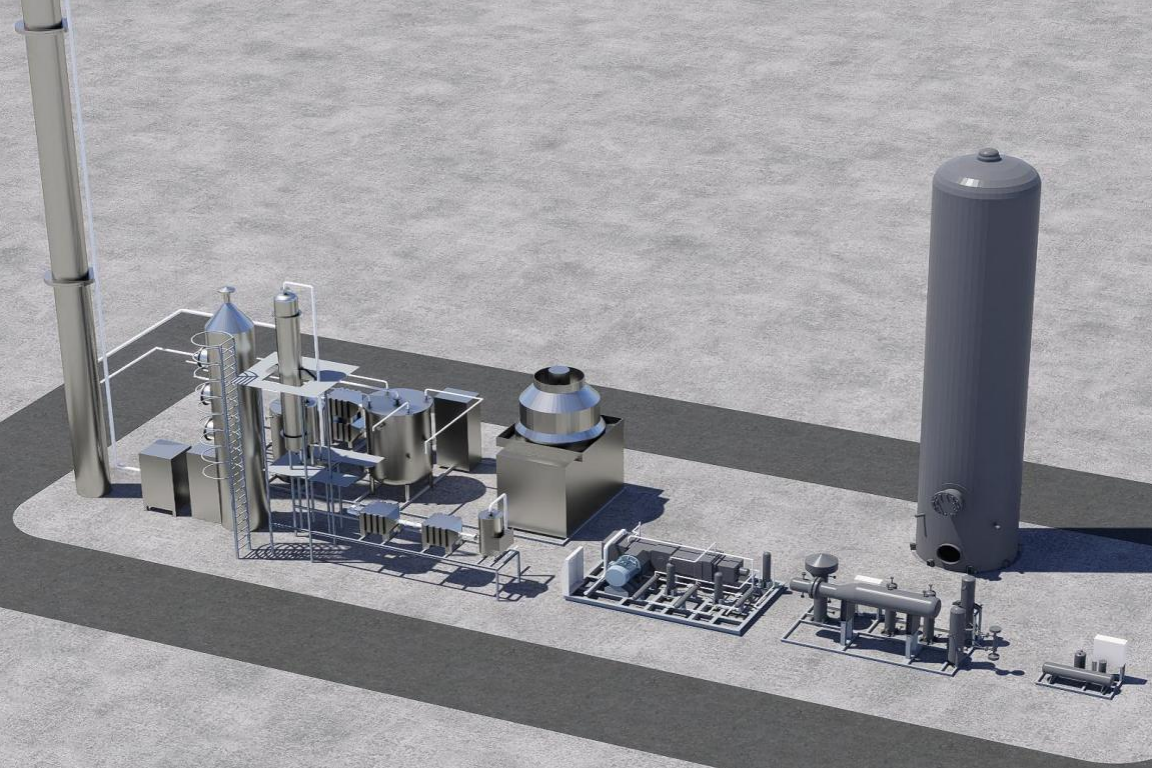

The 1,000-ton carbon dioxide capture, liquefaction and purification pilot plant built by CERI has been completed and is now operational, marking the first application of phase-change absorption technology in the iron and steel industry. After three months of continuous operation, the carbon dioxide capture rate has stabilized at over 90%, with an average regeneration energy consumption of approximately 2.1 GJ/t of carbon dioxide, which is about 45% lower than that of traditional MEA absorption methods. The captured carbon dioxide can be converted into valuable resources, producing food-grade liquid carbon dioxide through medium-pressure compression, adsorption, liquefaction, and distillation. This approach not only achieves carbon emission reduction but also makes it feasible to transform carbon dioxide into valuable resources, generating economic benefits. This technology can be applied to flue gas from blast furnaces, heating furnaces, lime kilns, and other areas within the steel industry, as well as from coal-fired boilers.

Deploying CCUS to Promote Green and Low-carbon Development of the Industry

Through the evaluation of energy consumption, carbon emission reduction, and technology's economic viability in kiloton-scale industrial tests, we can scientifically verify both common technologies and advanced equipment for carbon dioxide capture. This process promotes the large-scale industrial application of carbon capture, utilization, and storage (CCUS) technology and explores effective pathways for the green and low-carbon development of the iron and steel industry.