CERI: Improving Quality with Intelligence and Continuously Enhancing the "Green" Content of the Industry

CERI Digital Technology (Beijing) Co., Ltd. (CERI Digital Technology) fulfills its social responsibilities as a central enterprise and contributes to building ecological environment management systems. The company has engaged in the development of standards such as the Technical Requirements for Energy Management and Control Systems of Smart Factories in the Iron and Steel Industry, the Technical Requirements for Intelligent Power Grid Management and Control Systems in the Iron and Steel Industry, and the Ultra-Low Emission Design Specifications for Iron and Steel Enterprises. The company promotes concerted efforts to cut carbon emissions, reduce pollution, expand green development, and pursue economic growth, thereby contributing "green wisdom" to the goals of carbon peaking and carbon neutrality while fostering high-quality development.

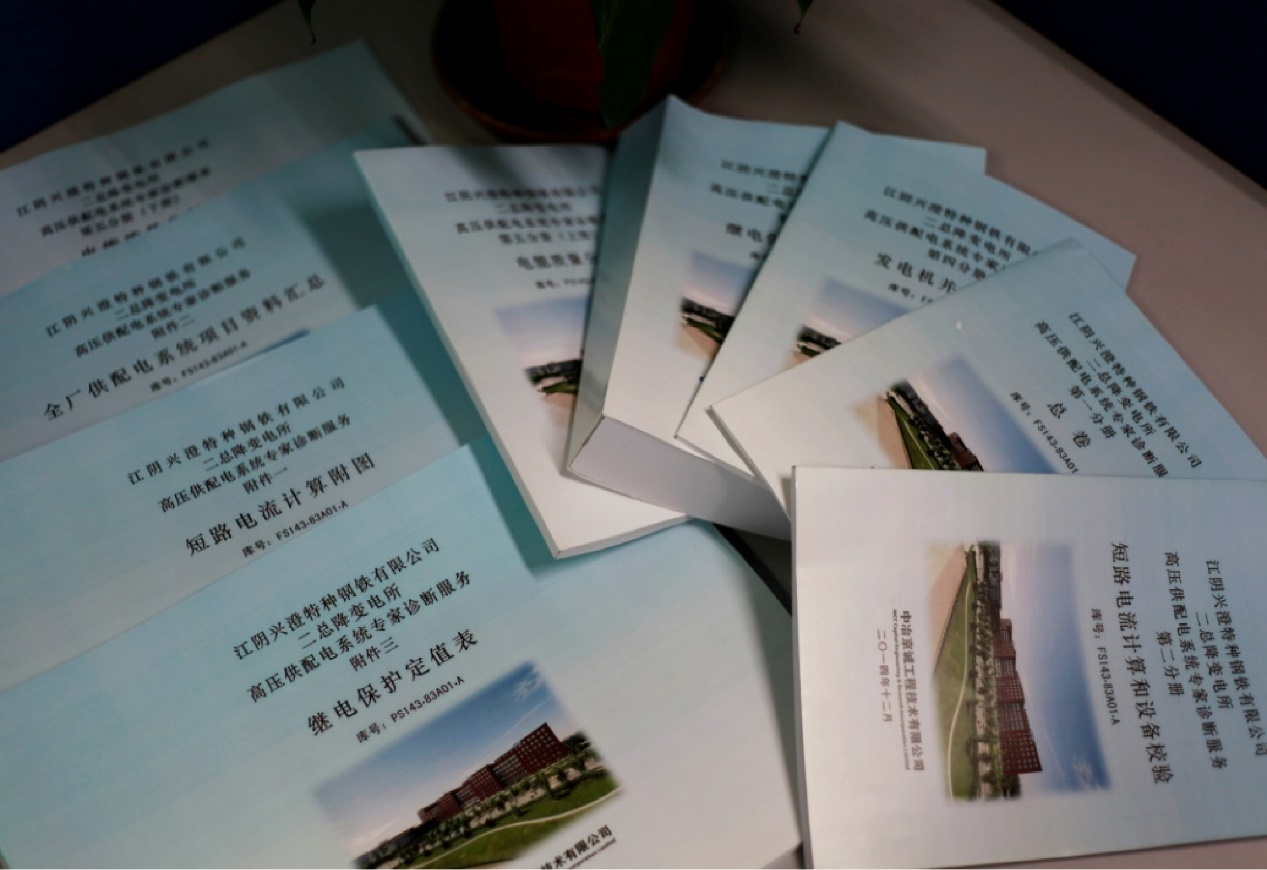

CERI Digital Technology also focuses on energy diagnosis and consulting to guide the implementation of corporate green strategies. Embracing the principles of "ecological priority, economical and intensive development, and green low-carbon development," the company concentrates on key areas and critical aspects of green and low-carbon progress. It assists traditional industries in transitioning towards energy conservation and carbon reduction and supports emerging industries in their green and low-carbon growth. CERI Digital Technology provides enterprises with low-carbon, efficient, and intelligent solutions encompassing planning and design, diagnostic consultation, system construction, and operational management to help achieve their green and low-carbon development goals. The energy diagnosis service offered by CERI Digital Technology fully considers the specific characteristics of various enterprises, delivering comprehensive diagnosis services and one-stop solutions focused on safety, reliability, and cost-effectiveness for the entire factory's energy systems. It establishes whole-factory energy databases and calculation models, integrates a self-developed data decision-making system, and proposes optimal correction plans for existing issues. This approach helps both new and existing factories tap into their energy-saving potential, improve energy utilization efficiency, reduce production and operational costs, and provide users with a data-driven, visualized, and standardized energy usage experience. So far, CERI Digital Technology has served over 40 industrial enterprises, including Shiheng Special Steel, Xingcheng Special Steel, Laoting Steel, and Lianyuan Steel, facilitating green, intelligent, and high-quality development within the manufacturing industry.

Energy Diagnosis and Analysis Report

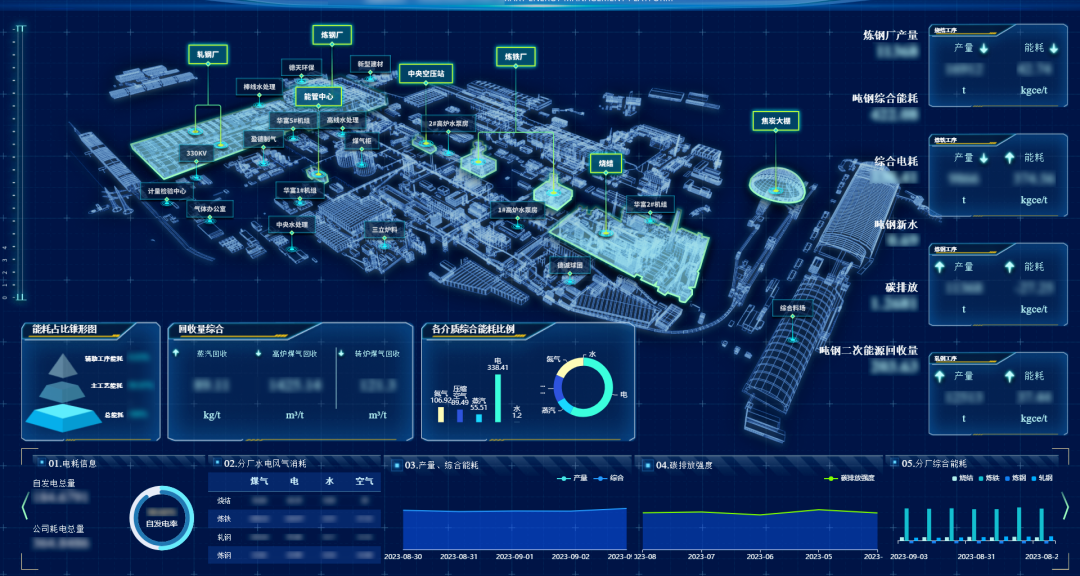

The energy management and control system drives the green, digital, and intelligent upgrading of the industry. CERI Digital Technology is committed to transforming and upgrading traditional industries through green technology. By adhering to the principles of green and intelligent construction, the company integrates new-generation information technologies such as the industrial Internet, big data, artificial intelligence, and 5G to develop energy forecasting and dispatching models. This approach enables integrated, efficient, and intelligent operation and maintenance management of water, electricity, air, and gas systems in industrial enterprises. As a result, enterprises can enhance their comprehensive energy-saving benefits by 0.3%, reduce carbon dioxide emissions by approximately 320,000 tons, and cut down the cost per ton of steel by more than RMB 30. This translates to annual savings of about RMB 300 million for ten-million-ton iron and steel companies, achieving significant economic and social benefits. The company's efforts contribute positively to cost reduction, efficiency improvements, energy conservation, and carbon reduction, as well as the advancement of ultra-premium energy efficiency in high-energy-consuming industries, thereby facilitating the green development of industrial enterprises. The products have been successfully implemented in smart energy projects at Lingyuan Steel, Jiyuan Steel, Shaanxi Hanzhong Steel, Fengnan Steel, Shiheng Special Steel, and Linyi Iron and Steel Investment Group Special Steel Co., Ltd. Relevant achievements have been evaluated by the Chinese Society for Metals and recognized as reaching international leading levels. They have been included in the "National Industrial Energy-Saving Technology Recommended Catalog" by the Ministry of Industry and Information Technology, as well as in the "Typical Cases of Internet of Things Empowering Industrial Development in 2024" released by the Ministry of Industry and Information Technology, and the "Recommended Catalog of Intelligent Manufacturing Solutions for the Iron and Steel Industry (2023)" issued by the China Iron and Steel Association. Additionally, the products were recognized as one of the Top Ten Excellent Solutions for Intelligent Manufacturing in the Iron and Steel Industry in 2022 and have received several honors, including the First Prize for Computer Software in Excellent Engineering Survey and Design in the National Metallurgical Industry in 2020.

Smart Energy Management and Control System

Green and low-carbon development is the inherent requirement of new quality productive forces, and implementing green and low-carbon development mechanisms is critical for their advancement. CERI Digital Technology promotes coordinated emission reductions of multiple pollutants. It has established China's first system that integrates the production processes and environmental management operations of iron and steel enterprises through 5G technology. This system encompasses key functions, including management of waste gas emissions, comprehensive wastewater management, comprehensive solid waste management, and comprehensive environmental protection management. It effectively shapes the digital carbon flow within the entire factory, achieving multi-dimensional integration of environmental management elements in iron and steel enterprises and enhancing their environmental management efficiency by over 25%. The company's contributions have been pivotal in supporting the green transition of over ten iron and steel enterprises, including WISCO, China South Steel, Baowu Echeng Steel, Shaanxi Steel Group Longsteel, and Jiangyin Xingcheng Special Steel. Relevant achievements have been recognized as reaching an internationally leading level by the Chinese Society for Metals. Furthermore, in 2024, the company was awarded the "Excellent Practice Case of Internet Development in the Engineering Construction Industry" by the China Association of Construction Enterprise Management, as well as the first prize for National Outstanding Computer Software Achievements in the Metallurgical Industry.

Intelligent Ecological Environmental Protection Management and Control System