Hot Test Run of Thick Slab Caster Upgrading Project of Baogang Group Steel Sheet Mill Successfully Completed

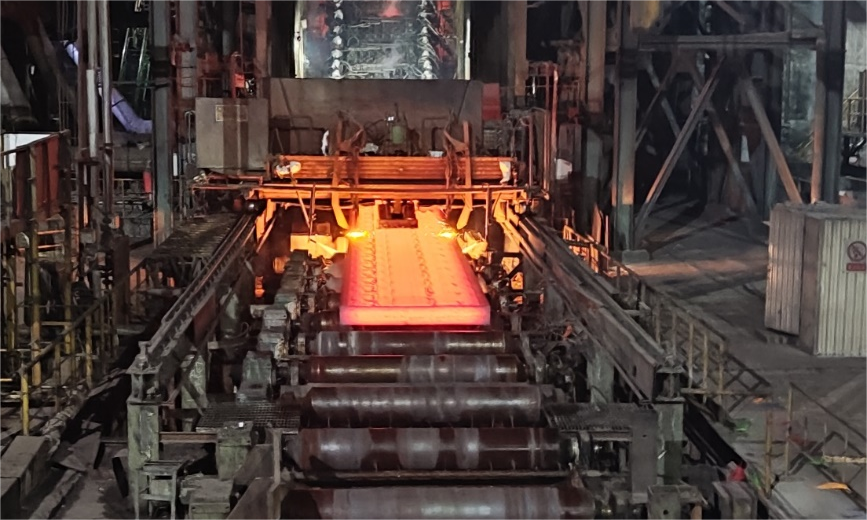

On October 25, the Slab Caster Dynamic Water Distribution and Dynamic Soft Reduction Upgrading Project of Baogang Group Steel Sheet Mill undertaken by CERI started the hot loaded test run with a specification of 250×2000 mm and a steel product grade of Q235B. At 4:13, the dummy bar was successfully disconnected. The equipment operated normally, the casting process was stable, and the hot loaded test run was successfully completed.

CERI undertook the integrated supply of mechanical equipment, I&C system and process modeling software for this upgrading project. It adopted a series of advanced technologies to solve problems such as billet jamming and poor quality of billets caused by the aging of existing casters and obsolete control schemes.

The design team of CERI faced challenges such as limited valve station space and insufficient basic data. To overcome these challenges, the team visited the site multiple times to understand the Employer's requirements. They optimized the design to maximize the utilization of existing mechanical equipment, control devices, and on-site pipelines. This resulted in a significant reduction in the overall implementation period of the project.