Ling Steel Group Large Bar Production Line Digital Project of CERI Digital Technology Co., Ltd. Successfully Launches

On June 30, the large bar production line digital construction project for high-quality and special steel of Ling Steel Group led by CERI Digital Technology Co., Ltd. was successfully launched.

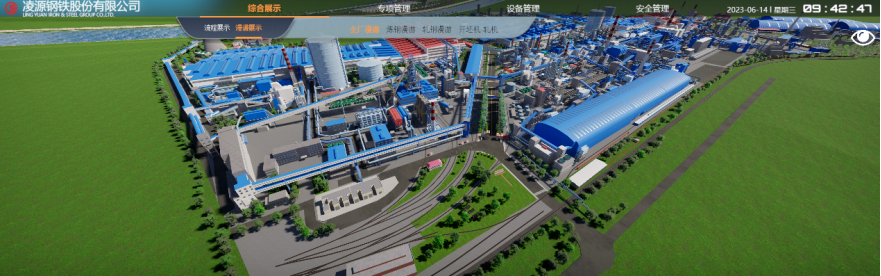

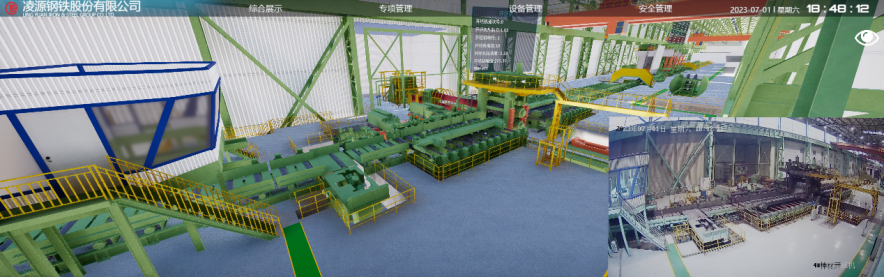

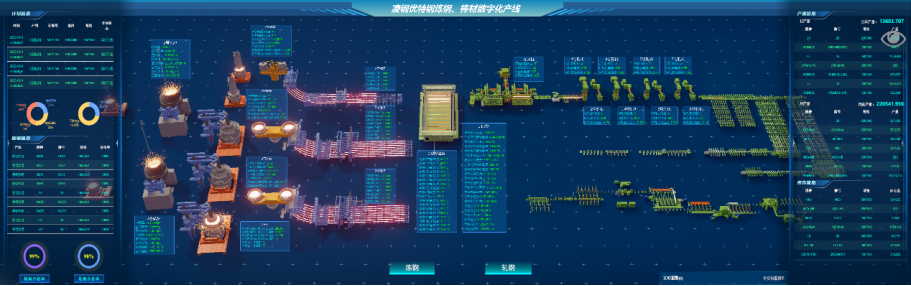

CERI Digital Technology Co., Ltd. is responsible for the adaptive transformation of equipment and control systems, manufacturing execution platform, quality big data platform and digital twin platform of the project. Through the application of new-generation information technology such as industrial Internet, big data, cloud computing, digital twin and artificial intelligence, the process control, process quality analysis and tracing, and production cost process control of intelligent optimization model of high-quality and special steel will be realized, and a visual, controllable and manageable digital twin production line will be built, which will help Ling Steel Group achieve the goals of the most stable quality, the highest efficiency and the lowest cost.

Through intelligent applications such as automatic, unmanned and less-manned technologies and robots, the project will build a technologically leading domestic intelligent and efficient bar production line to improve the automatic and lean production level of the production line. A significant amount of data related to design, production, operation, inspection and testing, monitoring, decision-making and indicators throughout the entire production line for steel rolling and utilities and auxiliaries will be uniformly collected, cleaned and stored, and the data will be deeply analyzed, processed and converted in combination with the business module of big data intelligent interconnection platform. It greatly improves the utilization value of production process data and the collaborative ability of production lines. The project utilizes the integration of big data platform to realize data extraction, analysis and result presentation, and improve the efficiency of production management. Through data collection and quality evaluation, strategies for optimizing and improving different links of the production line are obtained to improve the efficiency of quality analysis and the level of quality control. The three-dimensional digital model is established, and the production process data, equipment data, video data and three-dimensional modeling technology are combined to realize digital twin and improve the digital management and control level of the production line. Analytical tools are used for real-time diagnosis and optimization, and data is integrated through a powerful big data application platform to establish a data foundation for intelligent manufacturing.