The unmanned logistics metering system Intelligent Manufacturing Project is launched and put into trial in Linyi Special Steel

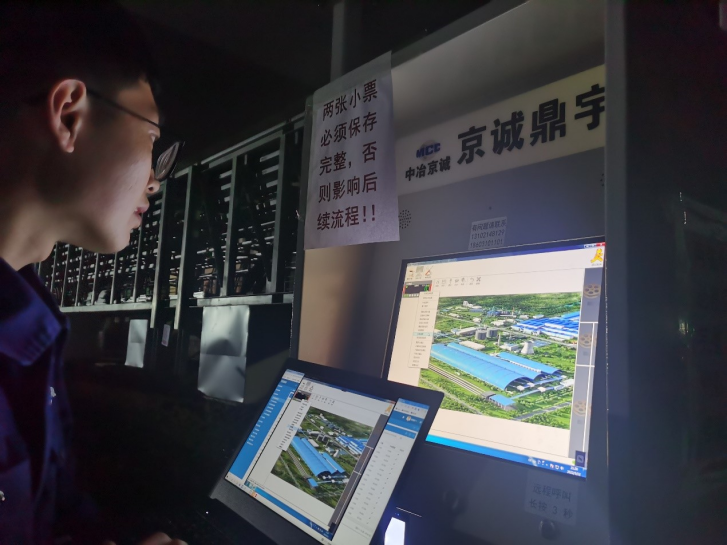

Recently, the unmanned logistics metering system of CERI for Linyi Special Steel Intelligent Manufacturing Project was successfully launched and put into trial operation. The system realizes whole-process contactless business handling from dispatching vehicles, entering factories, measuring, unloading to leaving factories, which provides a strong logistics guarantee for the timely supply of raw and auxiliary fuels needed for the hot trial production of Linyi Special Steel Project under the epidemic situation, and also marks a solid step in the intelligent construction of the whole plant of Linyi Iron and Steel Investment Group Special Steel Co. generally contracted by CERI Dingyu Co.

CERI Unmanned Logistics Metering System is an intelligent logistics and metering control system dedicated to the purchase transportation of bulk materials, the transportation of materials in iron and steel plants, and the sales transportation of all kinds of finished steel products for iron and steel enterprises. The system organically integrates the logistics metering system with digital twin technology, combines industrial Internet, situational awareness, edge computing and 5G technology etc. and sensing intelligent terminal products, creates an AI monitoring video network of logistics factory area, and builds a smart logistics factory area for iron and steel enterprises.

The unmanned logistics metering system has three advantages:

(1) Unattended operation and improved efficiency. The application of RPA, video monitoring, infrared radiation, intelligent access control, RFID electronic license plate and other technologies and facilities can automatically simulate the process of human-computer interaction, realize the linkage of multiple systems, and string up a series of operation processes in an automatic manner, greatly reducing the labor cost and improving the operation efficiency, and truly realizing the unmanned operation of logistics metering management system.

(2) Real-time feedback and dynamic tracking. The application of special data algorithm, combined with the technologies such as Internet of Things and Internet of Vehicles, realizes real-time scheduling, real-time supervision and real-time optimization of in-plant transportation.

(3) Intelligent devices for "light speed" warning. The utilization of AI image recognition and edge computing technology allows the millisecond real-time accurate collection of such information as persons, vehicles, goods etc. in the in-plant transportation process. The intelligent video analysis can replace human eyes to find abnormal conditions in real time, and timely link the alarm to realize intelligent application of monitoring equipment.