Intelligent overall solution of CERI new generation of high speed bar and rod workshop launched officially

Recently, the 4580 bar and rod production line of China Baowu Group Kunming Iron & Steel Co., Ltd which applied the new generation bar and rod intelligent workshop of CERI was put into operation officially, intelligent and centralized control production of “One Room for Two Lines” has been adopted, the new breakthrough of intelligent technology in the field of high speed bar and rod of CERI has been realized, which is highly recognized and praised by the owners.

The 4580 bar and rod production line of Kunming Iron & Steel Co., Ltd includes a boutique high speed bar and rod production line with annual output of 0.45 million tons and a high speed bar and rod production line with annual output of 0.8 million tons. High speed bar and rod production line has adopted the first domestic RSB modular unit designed and researched by CERI, the maximum operation speed of equipment is 115m/s, and the product accuracy and quality have reached to the international advanced level. High speed bar and rod production line has adopted the concept of flexible and modular rolling, and applied the international first single-pass high speed bar rolling technology. The maximum speed can reach 45m/s stably, which represents the highest level of the current high speed bar production line.

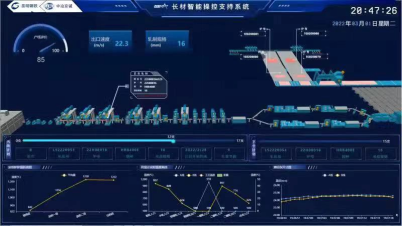

According to the principle and requirement of the intelligent manufacturing in China Baowu Group, the 4580 bar and rod project of Kunming Iron & Steel plans to combine intelligent control center of high rod and high bar production line, to realize the “One Room for Two Lines”. Under this centralized control mode, areas and equipment requiring concern from operators are increased, and the labour intensity is increased, it is difficult to timely find the potential problems of production line. In this regard, for the process features of bar and rod production line and centralized control demands, CERI intelligent group, depending on the rich experience on high rod and high bar intelligent control, has applied machine vision, the data analysis, artificial intelligence and other advance technologies on the base of advance and mature automatic system, and has successfully built overall solution of the new generation high speed bar and rod workshop intelligent.

This solution is based on the core problems concerned by the production line, according to visual tools, trend and causality analysis and predictive judgment, to make operators have a real-time and deeply understanding of the health status of production line, production bottleneck, product full-life quality files and other information. According to combining the mechanism model with data analysis model, real-time optimization and auxiliary decision-making of the parameters of the automatic system are realized, which solved the practical problems that limit production such as virtual measurement of the bar tolerance, the optimization of the extension of the multiple ruler and shearing short ruler, analysis and judgement of the stack-pull relationship among the racks and automatic optimization of tapping compartment. The production and quality are more stable after implementation, high effective operation and “One Room for Two Lines” are finally realized.